| Page

d'Accueil |

Qui sommes nous? |

Contact |

| Part Number: H1000 |

|

| Details & Specifications |

|

REQUIREMENTS AND TEST METHODS Test methods in accordance with International Standard IEC 1196. Mechanical characteristics 1. Inner conductor. Diameter:

2.62

mm ± 0.03 mm 2. Dielectric: Diameter:

7.15

mm ± 0.2 mm Centricity:

≥0.85 Adhesion:

41

– 410 N at 50 mm 3. Outer conductor: Diameter screen:

7.8

mm ± 0.25 mm Foil overlap:

>2 mm Coverage braid:

49

% ± 5 % 4. Sheath: Diameter:

10.3

mm ± 0.3 mm Tensile strength:

≥ 12.5 N/mm˛ Elongation at break:

≥ 150 % 5. Cable: Crush resistance of cable:

< 1% (load of 700N) Storage/operating temperature:

-40°C to +70°C Minimum installation temperature:

-5 °C Minimum static bend radius:

100 mm Electrical characteristics Mean characteristic impedance:

50

± 2 Ohms Regularity of impedance:

>

46 dB DC loop resistance:

≤15.5 Ohms/km DC resistance inner conductor:

≤3.5 Ohms/km DC resistance outer conductor:

≤12.0 Ohms/km Capacitance:

80

pF/m ± 3 pF/m Velocity ratio:

0.83

± 0.02 Insulation resistance:

>

104 MOhms.km Voltage test of dielectric:

3

kVdc Screening efficiency 30-1000 MHz:

≥90

dB Attenuation at Nominal Attenuation at Nominal 5 MHz:

0.8

dB/100m 1000 MHz: 14.0 dB/100m 50 MHz: 2.8

dB/100m 1350 MHz: 16.7 dB/100m 100 MHz: 4.0

dB/100m 1750 MHz: 19.5 dB/100m 200 MHz: 5.7

dB/100m 2150 MHz: 22.1

dB/100m 400 MHz: 8.4

dB/100m 2400 MHz: 23.6

dB/100m 600 MHz: 10.5

dB/100m 5000 MHz: 37.4 dB/100m 800 MHz: 12.3

dB/100m 10000 MHz: 59.3 dB/100m |

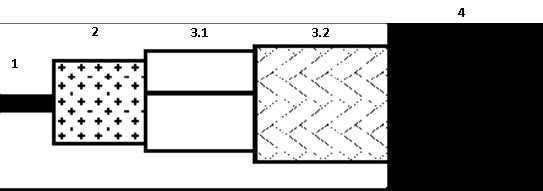

| Technical Illustration |

1 :Inner conductor Solid soft annealed copper 2 :Dielectric Gas injected PE 3.1 :Foil Copper polyester 3.2 :Braid Annealed copper 4 :Sheath PVC according the European Standard HD 624. |